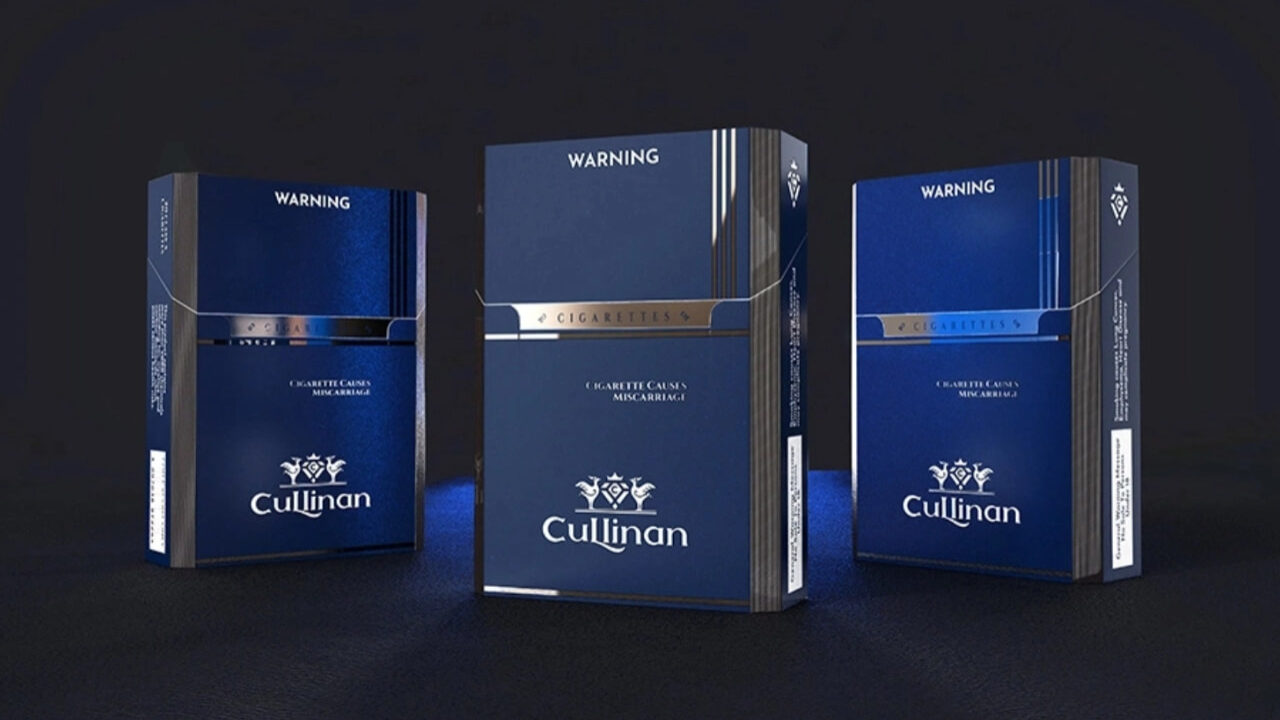

The first impression of any brand of cigarettes is determined by packaging. A bold design is what will make a customer take up a product or leave it unnoticed. The light blue cigarette box stands out from the crowd of ordinary tones, such as black, white, and gold. Its new cool appearance is beautiful to contemporary customers. Light blue, however, is challenging to produce. The inconsistency of printing this shade is also prone to failure, as it would undermine the brand identity and compromise compliance standards. This is a problem that must be addressed to establish credibility in a competitive market.

The Distinctive Appeal of Light Blue in Cigarette Packaging

Light blue is a calming, fresh, and exclusive color. It links with feelings of trust and balance. This shade is a departure from retail shelves. The uniqueness helps brands gain instant publicity. A steady color reinforces recognition, which indicates high quality. The regularity of color gives the customer confidence, whereas the irregularity casts doubt. Having a perfect shade of light blue assists brand image and consumer confidence.

Challenges in Printing Light Blue Packaging

Light blue is very sensitive to printing changes. Even small changes in ink density are visible. Minor machine calibration or substrate absorption variations are easily visible in lighter colors. Light colors, in contrast to darker ones, magnify flaws. The dangers involve darkened effects, spotty surfaces, and dark tones. Any minor change will push the shade to either green or gray, resulting in off-brand outcomes. These problems tarnish credibility and even seem to imply that packaging is fake.

Precision in Color Selection and Matching

Light blue needs to be defined as an actual color. Precision is achieved by using precise Pantone or CMYK codes. Errors are minimized through professional prepress preparation, which establishes uniform parameters. Proofing systems are a preview, allowing you to check the correctness before printing in large quantities. Test runs identify discrepancies and enable machines to be calibrated. Printers stabilize color balance by checking each step of the process. This action avoids design intent and final output misalignment.

Advanced Printing Techniques for Consistency

The method of choice in producing sharpness and fidelity is offset printing. The technology is used to replicate light shades with greater vibrancy. Special coatings are also of crucial importance. UV colors are used to ensure color retention, and aqueous finishes are used to prevent fading. Heidelberg machines and UV systems offer high accuracy and are well-suited for large-volume printing. These are such that they reproduce uniformly and do not change color between batches. The use of sophisticated technology reduces wastage and ensures that every box is similar to the approved sample.

Material and Finish Considerations

The light blue appearance after printing depends on the substrate. Ink absorption and reflection are determined by paperboard type. Gloss-coated boards reflect light, while matte surfaces absorb it. Lamination is another control level. The selection of the appropriate material guarantees ink behavior and predictability. Stability in the choice of substrates will avoid unpredictable changes between production cycles.

Enhancing Light Blue Packaging with Custom Elements

A light blue consistency does not restrict design creativity. Additions like embossing, foil stamping, and spot UV are elegant. Foils made of metals also add to the soft shade without breaking the composition. Brand logos are emphasized with embossing, whereas spot UV provides subtle contrasts. These facts render the box high-end without losing homogeneity in color. Personalization with accurate technology contributes to uniqueness and perfect consistency.

Regulatory and Branding Compliance in Cigarette Packaging

The packaging of cigarettes should adhere to stringent international standards. Font size, font placement, and health warnings are not negotiable. Light blue designs need to incorporate these needs while still maintaining their attractiveness. Professional competence will assure conformance and innovative expression. A company that has experience in the international market knows how to strike a balance between the two. The outcome is that it produces packaging that adds value to the brand without being illegal. Color stability also helps to demonstrate authenticity and build a stronger relationship with the authorities and customers.

Conclusion

It is an art and science to print light blue cigarette boxes without inconsistency. This is a delicate shade which needs precision, sophisticated equipment, and stringent quality assurance. Correct codes, correct substrates, and rigorous checks guarantee consistent results. Improvements will add attractiveness without compromising uniformity. With the cigarette brands, the perfect light blue is not just a design option. It is an indicator of quality, compliance, and brand integrity. Every successful box will give the customer an understanding that the product is a reputable one of high quality and should be purchased.