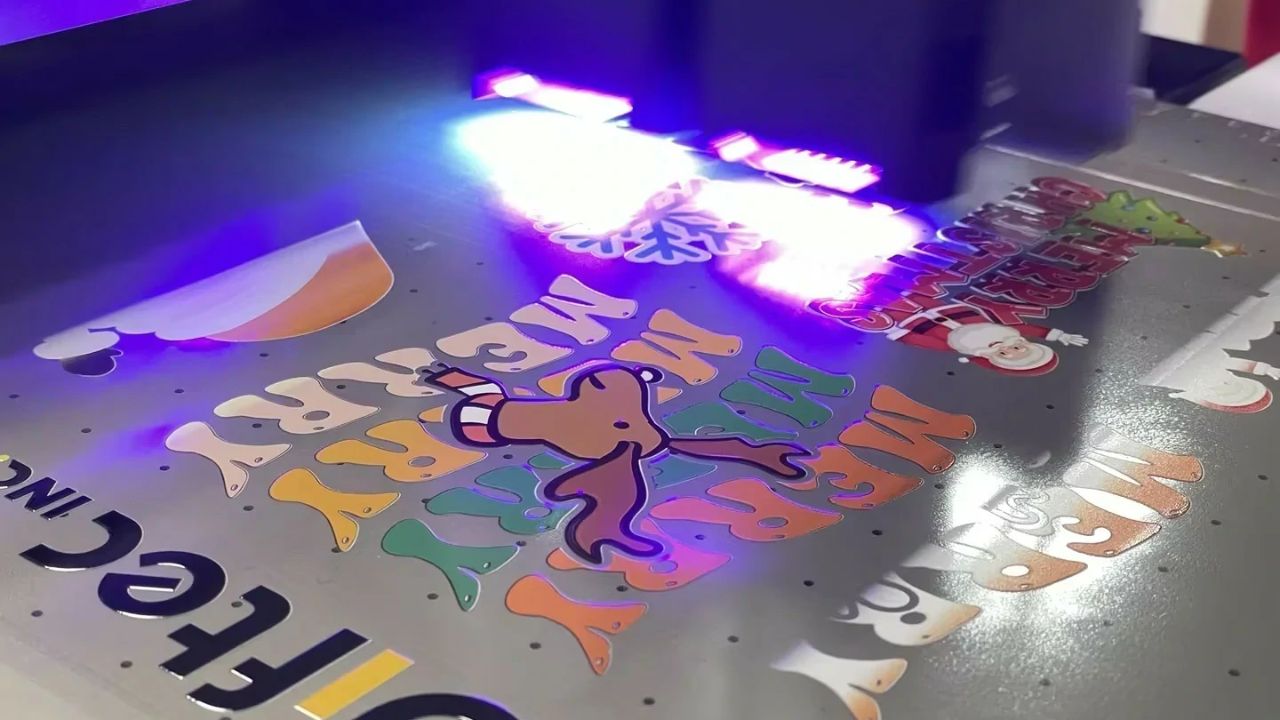

UV flatbed printers have revolutionized the printing industry because they inculcate vivid, high-resolution printing on a variety of types of materials that include but are not limited to acrylic, metal, glass, PVC, wood, and plastic. The printers are mandatory in case of signage, packaging, ornamentation, and customization of promo products. Nevertheless, due to its versatility and high technology, even the experienced users of this particular device make mistakes on a regular basis, and in some cases, beginners may encounter quick causes of bad results, reusing of materials, damaging of the item, or delays in manufacturing processes. Knowing and preventing these errors is important in ensuring maximum lifespan of the uv flatbed printer and stable quality.

Failure to Properly Prepare the Surface

Let it be noted that the preparation of the surface of the substrate is one of the least well-taken steps in UV flatbed printing. Most of the users can believe that they can print over any surface, but dust, oil, or moisture can interfere with ink adhesion. Smudging, an ink lift-off, or less durability can be caused by not cleaning and drying the substrate sufficiently prior to printing. Other papers, too, need some pre-treatment or primer to enable the ink to get bonded, particularly with glass or metal. Failure to go through this step of preparation results in unequal prints and poor product quality.

Ignoring Material Compatibility

Even though the UV flatbed printers give the user the ability to print on a wide scope of materials, not all surfaces would react similarly to UV ink. There are periods when the user assumes that it is always compatible and may ignore the fact that the media is UV-reactive or the ink will stick. This is especially so with supple materials or very absorbent materials. Selecting the unsuitable media may lead to cracking, fading, or poor curing of the ink. The main thing in eliminating failures in printing is to ensure that the material to be printed is UV-friendly and, where a test run is required.

Unsuitable Curing Conditions

UV flatbed printers operate through UV light to cure the ink and fix it on the material instantly. The wrong curing conditions (strength, time, or lamp position) may fail to produce the desired result. Print results can be either too tacky, easily scratched or smeared when under-cured, or cracked when so over-cured. The lamp power and exposure times need to be referred to by the manufacturer's guidelines at all times. It is also necessary to check regularly the condition and alignment of UV lamps to provide even and full curing on the print surface.

Neglecting Maintenance Schedule

A missed routine maintenance is one of the most harmful errors that appear in the work with a UV flatbed printer. Filters, ink systems, and printheads should be well cleaned to avoid obstruction and continuity of ink. Failure to do this maintenance may play out into failure to clean the nozzles, leading to formation of color banding as well as downtimes. The print quality and mechanical parts can also be hurt by the presence of dust within the machine. The operators are supposed to adhere to a rigid routine of cleaning, cleaning with the prescribed solutions, and ensuring the machine environment is clean and free of dust.

Missing Test Prints and Settings Check

It is a dangerous habit to forego test prints before undertaking production run jobs on this scale. One of the aspects that operators tend to overlook is the print settings such as the resolution, the pass mode, and the color profiles. Errors in such conditions may spoil entire inventories of material. Test printing enables one to check layout, color print, and media layout. It is particularly crucial in the cases when you have to deal with new materials or patterns. It eliminates material and time requirements in the long term and guarantees that the output print will be good.

Poor Training or Errors of Operators

UV flatbed printers are sophisticated to operate, despite their great automated functionality. There may be a situation when businesses task operators who have not received adequate training, which results in improper user practices and diminished efficiency. Output quality may be influenced by misinterpretation of software instructions, mishandling of media, or improper loading procedures. Comprehensive training and letting the operators familiarize themselves with the software and the hardware parts will eliminate any operational errors as well as increase productivity.

Conclusion

The possibilities of UV flatbed printers in creative and commercial fields are tremendous; however, only with proper maintenance, necessary attention to the process of operation, as well as proper use of the technology, can one achieve succinct results. Users can achieve long-term reliability and high-quality prints by avoiding the many user errors that sometimes occur, i.e., Surface preparation, curing settings, maintenance, and incorrect choice of paint or material in printing. As the right practices are adopted, however, instead of being efficient only, UV flatbed printing becomes a competitive edge in the contemporary printing environment.